Edge to Surface

This function can be used to measure for maximum deviation from the boundary of one surface to another surface in cases where tangency is desired when preparing to join surfaces.

A specified number of points will be distributed along the specified edge.

-

Each point will be evaluated for its minimum distance to the adjacent surface. Also, the surface normals at each point will be compared for parallelism.

-

If any points exceed a specified 'deviation tolerance' threshold or if any normals exceed a specified 'angular tolerance' threshold, this data will be reported back to you as permanent entities displayed on the screen. These tolerances can be adjusted at the parameter menu.

-

After evaluating, you will be notified as to how many, if any, of the specified points exceeded the positional deviation tolerance. Also, the location of these points will be displayed on the screen. Note that this information, as well as the information explained in steps 7 and 8, appears in the ”r;Data Verify” dialog.

-

Next, you will be notified as to how many, if any, of the normal vectors at the specified points exceeded the angular deviation tolerance. Also, the location of these vectors will be displayed on the screen.

-

Finally, you will be notified of the maximum positional and angular deviations and model the maximum deviations as point and vector entities.

Using the Function:

-

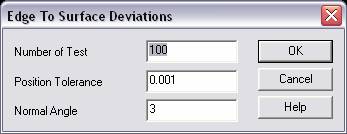

Select Edge to Surface from the Verify>Deviations submenu. The Edge to Surface Deviations dialog box appears.

-

Number of test points - Along the specified boundary.

-

Position Tolerance - The minimum positional deviation tolerance for which points will be displayed.

-

Normal Angle - The minimum angular deviation tolerance for which vectors will be displayed.

-

-

Accept the defaults, or specify new values for the available settings.

-

When all values are satisfactory, click OK to initiate the evaluation.

-

Select one surface for evaluation and an edge of another surface for confirmation.